Basic material - Swedish steel

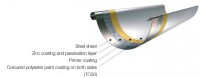

Lindab Rainline system components are made of hot-dip galvanized steel finished with a multi-layer paint coating.

In order to ensure long-term protection against corrosion, a 275 g/m2 zinc coating is applied to the steel sheet. Due to zinc ions on the surface the zinc coating naturally regenerates itself in case of an unintended scratch or cut, thus protecting steel from corrosion.

The final colouring layer (TC50) is a long lasting coating that gives the products an attractive, elegant shine. The applied multi-layer coating meets the strictest environmental protection requirements.

Coatings are applied to the galvanized steel surface with an even thickness, top quality and a strong adhesion during the manufacturing process.

Multi-layer coating technology consists of:

- hot-dip galvanized steel (275 g of zinc/m2)

- primer coating

- coloured polyester paint coating on both sides (50 µm)

- Brightness: 40 +/- 5

This basic material guarantees long life-span, sustaining high quality and excellent weather resistance for Lindab Rainline system even extrem bad weather conditions.